Right now, I know exactly where most leaders in the floral industry are living.

All eyes are on Valentine’s Day. Production schedules are being reviewed and locked. Freight is being chased. Labor is stretched. Teams are buried in meetings, spreadsheets, and late nights, all focused on executing the biggest holiday of the year without major failure.

At the same time, many growers and importers are absorbing a roughly 20% increase in the minimum wage in Colombia. Cost models that were already tight are being reopened. Add in geopolitical uncertainty following events in Venezuela and rising tension between President Gustavo Petro and President Trump, and it is no surprise that stressful conversations are intense and constant.

Purchase orders are being revisited. Numbers are being reworked. Scenarios are being modeled again and again.

This is what responsible leadership looks like under pressure.

But in the middle of this Valentine’s Day sprint, there is a question that deserves attention, even if it feels inconvenient to ask it right now.

Are your systems making this easier for you, or harder?

Peak holidays have a way of telling the truth. They expose friction, manual work, disconnected data, and outdated processes that stay hidden during calmer weeks. If Valentine’s Day feels heavier every year, that is not just market pressure. It is often a systems problem.

And while it may feel counterintuitive to lift your head when everything is urgent, this is exactly the moment leaders need to do it. Extraordinary things are happening in technology right now, not in theory but in production, and those advances are already reshaping cost, speed, and decision-making across retail and supply chains.

These tools will not save this Valentine’s Day. That window has largely closed.

But they can dramatically change how Mother’s Day feels.

And they can make next year’s Valentine’s Day far less chaotic and far more profitable than this one.

What the Curve Is Telling Us

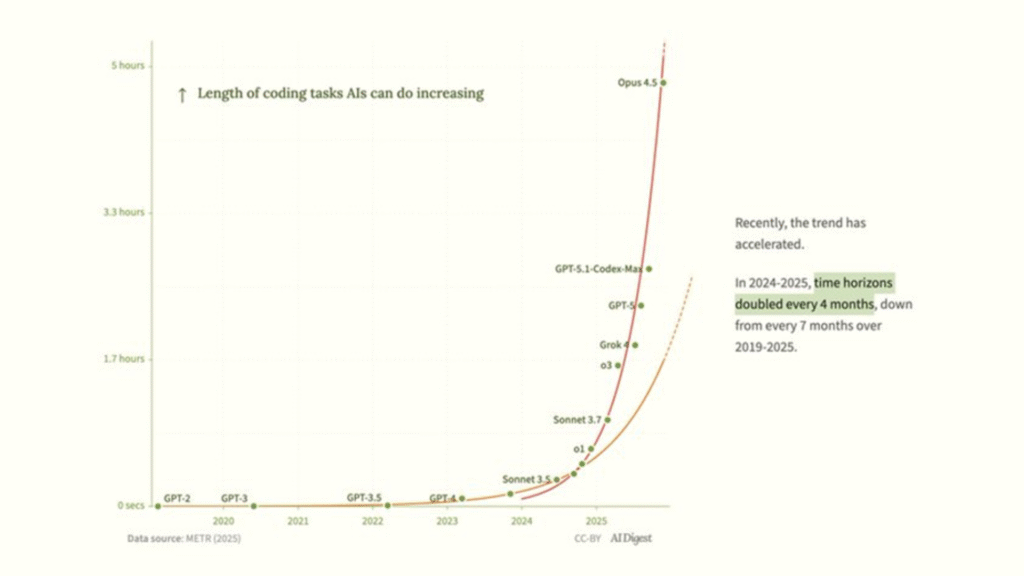

One of the clearest signals of what is changing comes from a simple but powerful chart tracking how long AI systems can work independently on complex tasks.

Early models could function for seconds. Then minutes. Then an hour.

Today, they can operate for multiple hours without human intervention.

More important than the absolute numbers is the rate of change. In 2024 and 2025, these time horizons have been doubling roughly every four months, far faster than the pace we saw just a few years ago, and completely blowing away “Moore’s Law,” which has tracked technology doubling every 18 months for half the cost since the 1950’s.

This is not a linear improvement curve. It is exponential acceleration.

Coding is not the story here. Coding is simply a proxy for sustained reasoning, multi-step planning, and execution without constant oversight.

Those are the same capabilities required to forecast demand, balance labor, reprice purchase orders, manage substitutions, and coordinate logistics across borders.

For years, many industries assumed AI would always need close human supervision.

That assumption is expiring quickly.

Think about what Valentine’s Day exposes every year. Emergency meetings. Late-night calls. Manual reforecasting. Decisions are made with partial data and human fatigue.

Now imagine systems that can run continuously for hours, simulate scenarios, rebalance plans, flag risk, and suggest alternatives calmly and instantly.

That does not replace leadership.

It replaces chaos.

Why the Curve Just Got Steeper

If the chart explains how fast AI capability is accelerating, what Nvidia just announced explains why that acceleration is about to explode across multiple fronts.

This is not hype. It is shipping infrastructure.

For a detailed breakdown, I encourage you to read this Forbes analysis.

Here is the short version.

NVIDIA’s new Vera Rubin AI supercomputer is already shipping, with full production having started weeks ago.

The new Reuben GPU is five times faster than the prior generation (Blackwell) while using only about 1.6 times the transistors.

That is roughly a 300 percent efficiency improvement.

This did not come from small tweaks. NVIDIA redesigned six core components at the same time: the Vera CPU, Reuben GPU, ConnectX-9 networking, BlueField-4 DPU, NVLink switches, and Spectrum-X Ethernet.

Every component was rebuilt together as one integrated system, a process Nvidia calls extreme co-design.

That matters because exponential systems are not built in silos. They are built as connected organisms.

The performance numbers are staggering. A single rack can now move 240 terabytes per second, roughly twice the bandwidth of the entire global internet, concentrated in one physical system.

At the same time, these systems run on warm water cooling at 45 degrees Celsius, eliminating chillers and saving an estimated 6 percent of global data center power.

Speed, efficiency, and scalability all moved forward at once.

NVIDIA also open-sourced AlphaMayo, the world’s first reasoning autonomous vehicle AI.

This is not a lab demo or a concept release. It is launching in full production vehicles, beginning with the Mercedes-Benz CLA this year, followed by Europe and Asia.

Because the model is open source, it accelerates development not just for cars, but for trucks, warehouses, agriculture, robotics, and logistics.

This is the infrastructure layer that allows AI systems to think longer, see better, and act in the physical world.

The Proof Is Already on the Road

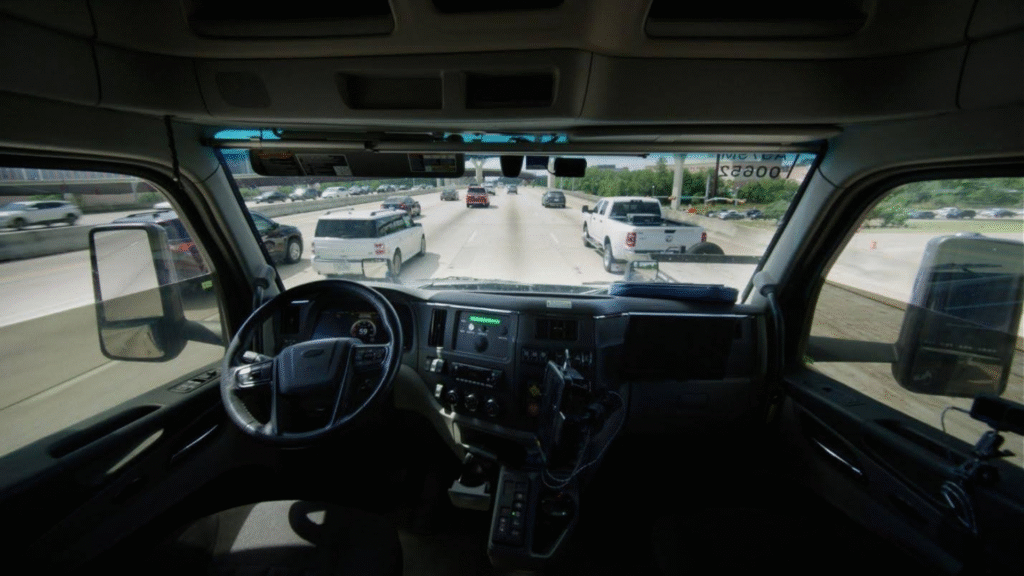

Which brings us back home to Texas.

Driverless trucks are no longer theoretical. Fort Worth has emerged as a real hub for autonomous commercial vehicles, and those trucks are already hauling freight on Texas highways today.

If you have not seen it yet, read this reporting from the Fort Worth Report.

The lead photo in that article is not a rendering or a stock image. It is proof that autonomous freight has crossed the line from future promise to operational reality.

So here is the question that matters.

Are your trucks autonomous?

If not, can you smell the cost savings rolling past you on I-10?

For the floral industry, the implications are enormous. Autonomous freight reduces exposure to driver shortages, hours-of-service limits, and unpredictable scheduling. Over time, it lowers freight costs, improves reliability, and reduces the number of holiday emergencies that drain teams and margins, all while delivering flowers faster, giving more days to retailers (reduced shrink) and to customers (longer life in their homes).

What This All Adds Up To

AI that can think longer. Supercomputing that removes bottlenecks. Robotics that move products. Autonomous vehicles that move freight.

These are not separate trends. They are the continuing evolution of the explosion of exponential technological growth, where the things we’ve been hearing about are beginning to deliver real impact in our physical world. And remember, everything I’ve discussed here will be TWICE AS POWERFUL AT HALF THE COST, well before Valentine’s Day 2026.

The companies that win over the next five years will not be the ones who simply worked harder during this Valentine’s Day.

They will be the ones who ensured their data was clean, their systems were connected, their leaders were learning, and their operations were ready to plug into what is already here.

This holiday may feel heavy, and that is understandable. But it is also revealing exactly where the friction lives and exactly where technology is about to erase it.

The trucks are rolling. The systems are thinking. The cost curves are bending.

Do you need help thinking through how you, as the leader of your floral business, should be engaging today with your team to be able to harness this and stay ahead of the curve in 2026?

I’m here and ready to help! Reach out to me on LinkedIn, or connect with me on my website, www.rockingbarz.com

About the Author

Joe Don Zetzsche is a transformative leader in retail marketing and operations with a passion for elevating customer experiences and fostering high-performing teams. As Vice President of BLOOMS Floral Marketing at H-E-B, he led the transformation of its floral business from a traditional supermarket department into an award-winning full-service floral shop—growing annual sales from $80M to over $300M and earning recognition as the fastest-growing floral business in the U.S. mass-market segment. Honored with the Produce Marketing Association Floral Marketer of the Year Award and the International Fresh Produce Association “Team of Six” Merger Award, Joe now owns and operates Rocking Bar Z, bringing the same commitment to innovation, excellence, and empowering talent to his own ventures.

Published by New Bloom Media

New Bloom Media (NBM) is the first multi-channel B2B media platform dedicated solely to the floral industry across the Americas. Through thought leadership, industry insights, and collaborative storytelling, NBM helps businesses innovate, connect, and thrive.

Want more floral industry insights?

Subscribe to our newsletter for exclusive interviews, market updates, and innovation spotlights delivered straight to your inbox.